Story #1

Compression systems for hydrogen liquefaction

Burckhardt Compression delivers compression systems to leading fuel cell and electrolyzer manufacturer Plug Power – for hydrogen liquefaction plants in the USA.

Following a first award of two compressors in March 2022, Joule Processing & Plug Power have again selected Burckhardt Compression to deliver 12 large hydrogen refrigeration compressors for six hydrogen liquefaction plants in the USA. These plants will be able to liquefy a total of 180 tons of hydrogen per day and will enable Plug Power to support its customers and existing network of 50‘000 fuel cells installed mostly in forklift trucks.

Growing hydrogen production network

The first plants will begin operation in 2023, with each plant able to liquefy 30 tons of hydrogen per day. These plants will be sold to third parties or become part of Plug Power‘s growing hydrogen production network in the USA.

Strategy to develop green hydrogen

Plug Power is one of the leading fuel cell and electrolyzer manufacturers and plans on building multiple hydrogen liquefaction (LH2) plants across the USA, as part of its green hydrogen development strategy. Joule Processing was acquired by Plug Power in January 2022 to apply its proven and energy efficient cryogenic process technology to hydrogen liquefaction.

Energy efficiency with compressors

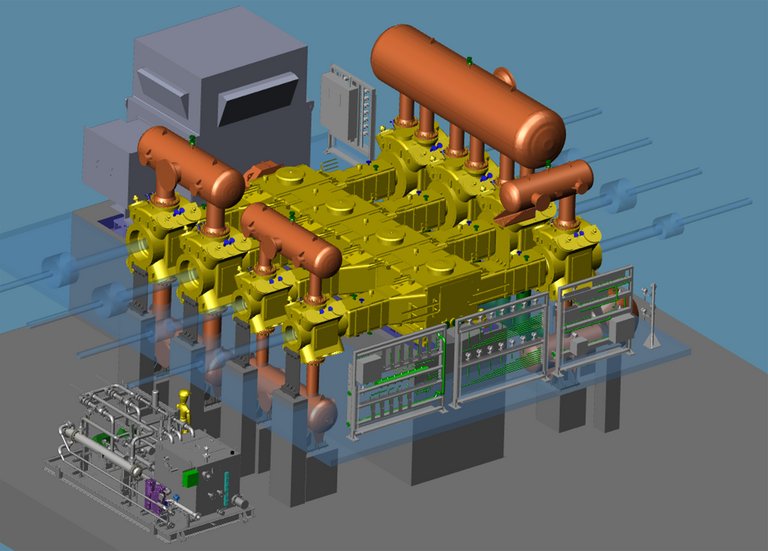

Burckhardt Compression‘s scope includes 12 hydrogen compressors including large synchronous motors and auxiliary equipment. The eight-cylinder machine designed around our third-largest compressor frame has been selected for its high degree of process flexibility and energy efficiency.

REDURA® oil sealing systems

As hydrogen compression for mobility and liquefaction applications must be totally oil-free, our solution includes the non-lubricated piston and packing sealing systems under developed in house the REDURA® brand, designed for unparalleled uptime and longest Mean Time Between Overhaul (MTBO).

1’000

tons per day of liquid hydrogen production by 2028.

Key success factors

A high level of continuous and rapid support to the client was essential in winning and executing this project. Burckhardt was able to fully support Plug Power, designing an excellent compressor to fit its specific process along with a short lead time and a commitment to ramp up production rates, helping to support the client‘s goal of up to 1‘000 tons per day of liquid hydrogen production by 2028. This substantial projects with Plug Power could pave the way to further exciting opportunities for hydrogen liquefaction plants on a global scale.